Thermametric Fabrics Private Limited operates as the primary Indian manufacturer of Furnace Refractory Expansion Joints provides superior solutions for industrial needs. The expansion joints from our company bridge thermal movements to protect refractory linings while optimizing furnace's operational life.

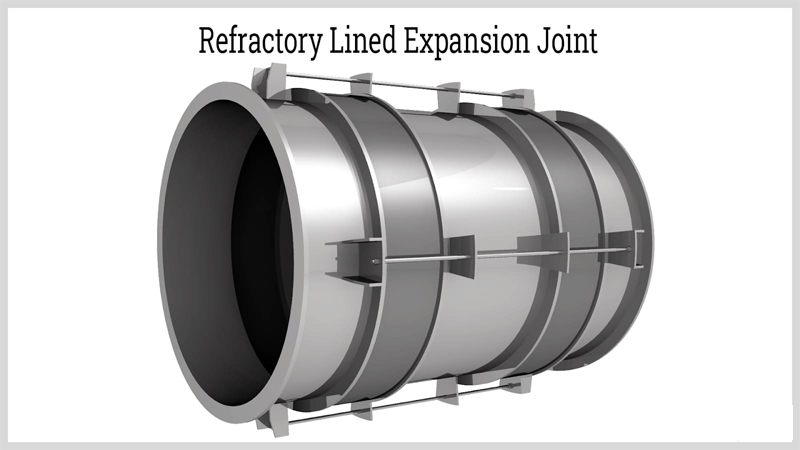

A Furnace Refractory Expansion Joint represents a specific sealing element that absorbs movement effects from temperature shifts in hot environments.

The Furnace Refractory Expansion Joint functions specifically as a sealing element to absorb movement triggered by high-temperature temperature changes in industrial applications. These joints serve as an essential protection method that stops furnaces along with kilns and industrial boilers from experiencing structural breakdowns while permitting continuous operation with enhanced efficiency.

These joints maintain peak resistance to high temperatures which ensures product efficiency.

These joints maintain peak resistance to high temperatures which ensures product efficiency. The material shows flexibility which enables movement absorption to stop stress that prevents cracks from forming in refractory linings.

The material shows flexibility which enables movement absorption to stop stress that prevents cracks from forming in refractory linings. The installation of thermal insulation properties in our product leads to better energy efficiency by preventing heat loss.

The installation of thermal insulation properties in our product leads to better energy efficiency by preventing heat loss. Industrial harsh conditions cannot affect the durability of products due to their corrosion and erosion resistance properties.

Industrial harsh conditions cannot affect the durability of products due to their corrosion and erosion resistance properties. The product offers customizable solutions through different industrial applications for which businesses can find solutions of various sizes shapes and materials.

The product offers customizable solutions through different industrial applications for which businesses can find solutions of various sizes shapes and materials. Structural Damage Prevention – The joints protect furnace linings from cracking which results from thermal stress.

Structural Damage Prevention – The joints protect furnace linings from cracking which results from thermal stress.

Multiple benefits occur because of better fuel efficiency which enables reduced operational costs.

Multiple benefits occur because of better fuel efficiency which enables reduced operational costs. The furnace benefits from safe operation due to its reliable sealing functions which prevent heat escape and leakage risks.

The furnace benefits from safe operation due to its reliable sealing functions which prevent heat escape and leakage risks. These high-quality materials ensure the joints serve demanding applications while requiring minimal maintenance.

These high-quality materials ensure the joints serve demanding applications while requiring minimal maintenance. The product demonstrates wide application possibilities in different industries that need high-temperature insulation solutions.

The product demonstrates wide application possibilities in different industries that need high-temperature insulation solutions. The steel metallurgy industry depends on this material to protect blast furnaces smelting units and ladle furnaces from extreme heat.

The steel metallurgy industry depends on this material to protect blast furnaces smelting units and ladle furnaces from extreme heat. Rotary kilns depend fundamentally on the Cement & Kiln Industry to prevent thermal damage.

Rotary kilns depend fundamentally on the Cement & Kiln Industry to prevent thermal damage. The product supports thermal power plants and industrial boilers by performing as an essential component for efficiency maintenance.

The product supports thermal power plants and industrial boilers by performing as an essential component for efficiency maintenance. The Petrochemical & Refining Industry relies on these products to support safe operation during refining furnace and heater applications.

The Petrochemical & Refining Industry relies on these products to support safe operation during refining furnace and heater applications. Glass and ceramics operations benefit from these fibrous materials because they defend high-temperature kilns together with processing units.

Glass and ceramics operations benefit from these fibrous materials because they defend high-temperature kilns together with processing units.As a leading manufacturer, Thermametric Fabrics Private Limited produces durable Furnace Refractory Expansion Joints that satisfy industry requirements of today. The solutions from our company deliver improved efficiency alongside durable and safety-oriented capabilities thus establishing ourselves as the leading company in advanced refractory sealing technology.

You can find customized solutions by contacting Thermametric Fabrics Private Limited right now.

Aluminium Potroom

Aluminium Potroom Carbon Bake Furnace

Carbon Bake Furnace Dust Filters and Air Filters

Dust Filters and Air Filters Fabrics & Ceramic

Fabrics & Ceramic High Temperature Metal Filtration

High Temperature Metal Filtration Technical Textiles

Technical Textiles Trough Filters

Trough Filters Flue End Seal

Flue End Seal Flue Ports

Flue Ports Furnace Curtain

Furnace Curtain Furnace Refractory Expansion Joints

Furnace Refractory Expansion Joints Launder Covers

Launder Covers Manifold

Manifold Non-Asbestos Packing

Non-Asbestos Packing Peephole Cover

Peephole Cover Peephole Gasket

Peephole Gasket Pit Cover Blankets and Frames

Pit Cover Blankets and Frames Port Plate

Port Plate Porthole Cover

Porthole Cover Pot Bake Out Blankets

Pot Bake Out Blankets Side Main Seals

Side Main Seals Siphon Seals

Siphon Seals Spout Gaskets

Spout Gaskets Trough Covers

Trough Covers Welding Blanket

Welding Blanket Welding Curtain

Welding Curtain Aluminium Filtration Bag

Aluminium Filtration Bag© Copyright 2025 Thermametric Fabrics Private Limited | Design and SEO By Arsh Infosystems