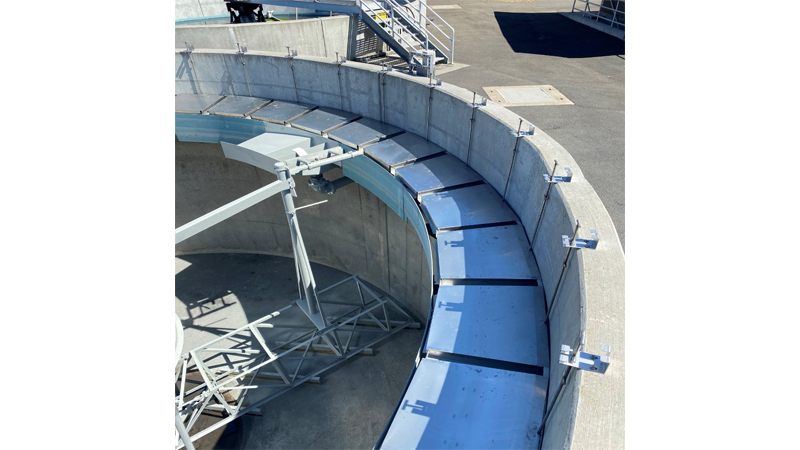

We are a Launder Covers Manufacturers in Madhya Pradesh, India. The Launder Covers from our company enhance performance by upholding heat retention and impurity reduction in molten metal processing systems.

The Launder Cover serves as an industrial insulation tool which defends molten metal throughout launder system conduits in casting and refining operations. The insulation provided by these covers together with their capacity to stop oxidation enables metal processing industries to achieve maximum efficiency while lowering operating expenses.

High-quality thermal insulation prevents heat dissipation which helps preserve the desired temperature of flowing molten metal.

High-quality thermal insulation prevents heat dissipation which helps preserve the desired temperature of flowing molten metal. The prevention of contamination through our products protects molten metal from both airborne pollutants and oxidation processes

The prevention of contamination through our products protects molten metal from both airborne pollutants and oxidation processes High-Temperature Resistance: Built to withstand extreme temperatures in metal processing environments.

High-Temperature Resistance: Built to withstand extreme temperatures in metal processing environments. The product withstands long operating durations because it utilises high-quality fabrication materials throughout its structure.

The product withstands long operating durations because it utilises high-quality fabrication materials throughout its structure. Different launder system requirements are served by launder covers which exist in multiple sizes and configurations.

Different launder system requirements are served by launder covers which exist in multiple sizes and configurations. The usage of launder covers results in energy efficiency through heat retention within the system.

The usage of launder covers results in energy efficiency through heat retention within the system.

The metal quality remains enhanced through launder covers because they avoid metal oxidation and contamination resulting in improved final products.

The metal quality remains enhanced through launder covers because they avoid metal oxidation and contamination resulting in improved final products. The use of launder covers creates a safer workplace because workers experience fewer fumes and decreased risk of molten metal injuries.

The use of launder covers creates a safer workplace because workers experience fewer fumes and decreased risk of molten metal injuries. Launder covers generate cost efficiency through their ability to reduce both wasted materials and energy losses and promote efficient production expenditure management.

Launder covers generate cost efficiency through their ability to reduce both wasted materials and energy losses and promote efficient production expenditure management. Customizable Solutions: Adaptable to different industrial processes and operational needs.

Customizable Solutions: Adaptable to different industrial processes and operational needs. The aluminum production process requires these materials to retain heat while lowering the formation of dross.

The aluminum production process requires these materials to retain heat while lowering the formation of dross. In steel and foundry manufacturing operations Launder Covers protect molten metal from developing oxidation while being transferred.

In steel and foundry manufacturing operations Launder Covers protect molten metal from developing oxidation while being transferred. Non-Ferrous Metal Processing: Ensures contamination-free transportation of metals like zinc, copper, and magnesium.

Non-Ferrous Metal Processing: Ensures contamination-free transportation of metals like zinc, copper, and magnesium. Recycling facilities use Launder Covers to reach higher energy efficiency levels in their production of secondary metals.

Recycling facilities use Launder Covers to reach higher energy efficiency levels in their production of secondary metals. Automotive & Aerospace Industries: Improves quality control in metal casting applications

Automotive & Aerospace Industries: Improves quality control in metal casting applicationsThermametric Fabrics Private Limited delivers innovative Launder Covers that solve problems related to heat insulation and safety along with process optimization. The Launder Covers from Thermametric Fabrics maintain top-tier standards for modern metal processing facilities through their advanced design features. Our company understands the critical importance of precision insulated solutions so our products provide top-performance reliability across all applications.

Aluminium Potroom

Aluminium Potroom Carbon Bake Furnace

Carbon Bake Furnace Dust Filters and Air Filters

Dust Filters and Air Filters Fabrics & Ceramic

Fabrics & Ceramic High Temperature Metal Filtration

High Temperature Metal Filtration Technical Textiles

Technical Textiles Trough Filters

Trough Filters Flue End Seal

Flue End Seal Flue Ports

Flue Ports Furnace Curtain

Furnace Curtain Furnace Refractory Expansion Joints

Furnace Refractory Expansion Joints Launder Covers

Launder Covers Manifold

Manifold Non-Asbestos Packing

Non-Asbestos Packing Peephole Cover

Peephole Cover Peephole Gasket

Peephole Gasket Pit Cover Blankets and Frames

Pit Cover Blankets and Frames Port Plate

Port Plate Porthole Cover

Porthole Cover Pot Bake Out Blankets

Pot Bake Out Blankets Side Main Seals

Side Main Seals Siphon Seals

Siphon Seals Spout Gaskets

Spout Gaskets Trough Covers

Trough Covers Welding Blanket

Welding Blanket Welding Curtain

Welding Curtain Aluminium Filtration Bag

Aluminium Filtration Bag© Copyright 2025 Thermametric Fabrics Private Limited | Design and SEO By Arsh Infosystems